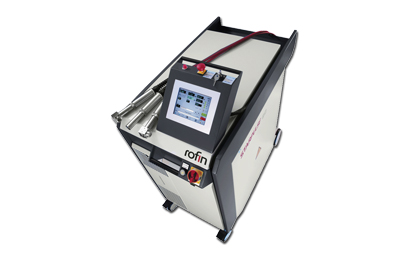

Pulsed YAG Lasers for Fine Welding Applications

The StarPulse laser sources (40 – 150 W) providing high pulse-to-pulse stability are ideal for laser welding of narrow seam geometries at high welding speeds – also for highly reflecting materials with high melting temperatures. High precision power output provides for pulse energies down to only few microns for micro welds of very fine components.

StarPulse lasers featuring excellent beam quality are first choice for the use of direct beam technology with large processing fields and small weld spot diameters at the same time. An extensive fiber kit allows flexiblity in positioning laser source and processing workstation and thus easy integration into production lines.

Features at a glance

- Laser power: 40 to 150 W

- Principle: lamp pumped rod laser

- Double closed loop power control

- Intra-pulse / Inter-pulse control

- Teach mode

- First-pulse control

- Single-Pulse graphics

- Touch screen

- Diagnosis + telephone support

- Process data collecting

- Direct beam

- Fine-welding option

- Fiber module